Painting of injection molded parts – the extra-plus when it comes to appearance

Whether it be automotive, household or electrical technology – almost all visible injection molded parts are painted for optical or functional reasons nowadays. Keune & Lauber fulfils the highest quality demands relating to this.

Painting plastic – a science in itself

While most materials can easily be covered with a coat of paint which increases their value, plastics are the exception to this rule. In contrast to metals, plastics are more elastic and can be warped by even the lightest touch. This is not a disadvantage of the molded parts; however, a non-elastic paint would rip relatively quickly. When it comes to painting plastic parts, a paint which still has a certain amount of elasticity when it has hardened is used, which means that it can move along with any changes to the shape of the substrate. As conventional paints do not stick to plastic, a special primer is also required.

A great variety of paint

The targeted coating of plastic surfaces does not only change the look and feel of the product, but also the overall appearance of the surface. This applies for both the automotive industry, where surface-related further processing significantly enhances the optics of the final product, and for the “white goods” industry, which has become much more colorful in recent years thanks to the improved range of surface finish options – to the delight of the consumer. Now, there is a wide range of finishes for plastic parts with paints available in various shades (according to RAL, NCS and other color collections) and several gloss levels (matte to high-gloss). The range of finishes is rounded off by soft and textured paints which produce interesting effects on plastic surfaces and therefore offer more creative leeway.

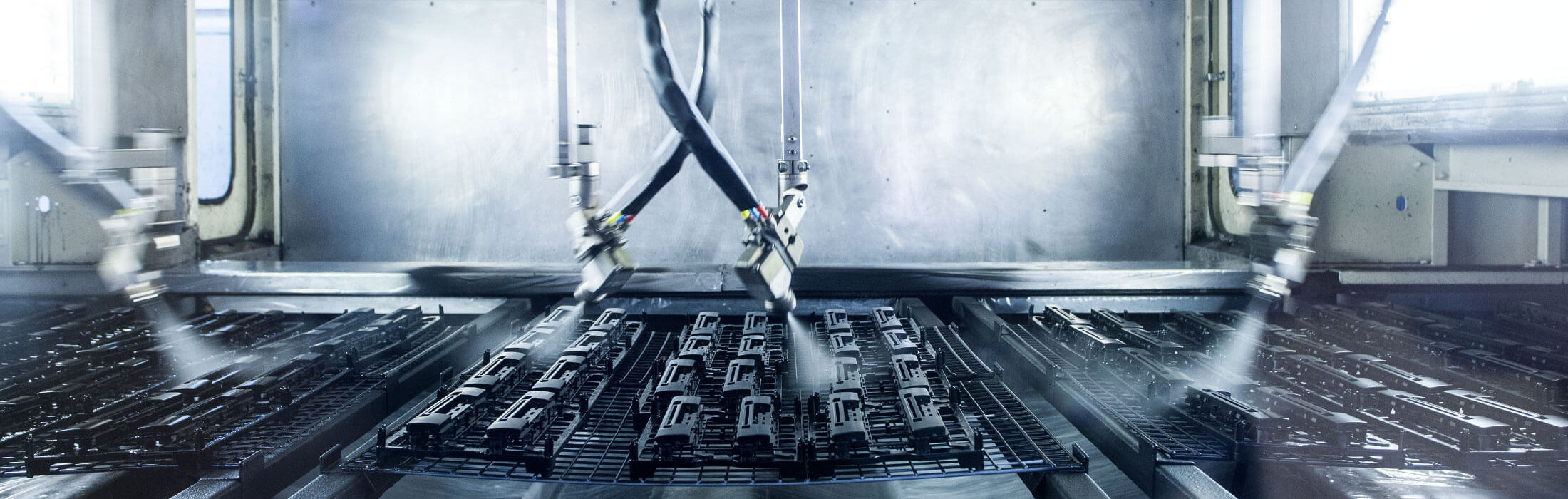

Plastic painting by Keune & Lauber

Keune & Lauber is your reliable partner when it comes to painting plastic parts. We can also realize perfect surfaces and visible surfaces in the same way that we can realize optical functionality and scratch resistance. A computer-controlled painting process ensures the reproducibility and stability of the painting parameters, including the thickness of the coating. Alongside water-soluble and solvent paint, we also manufacture UV varnishing systems for matte, high-gloss and textured class A surfaces.

Environmental relevance in production

The painting of injection molded parts is associated with emissions being released into water and into the air as well as with the generation of waste. We strive to acknowledge any environmental impacts caused by our paint shop, and to reduce this as much as possible through appropriate measures.