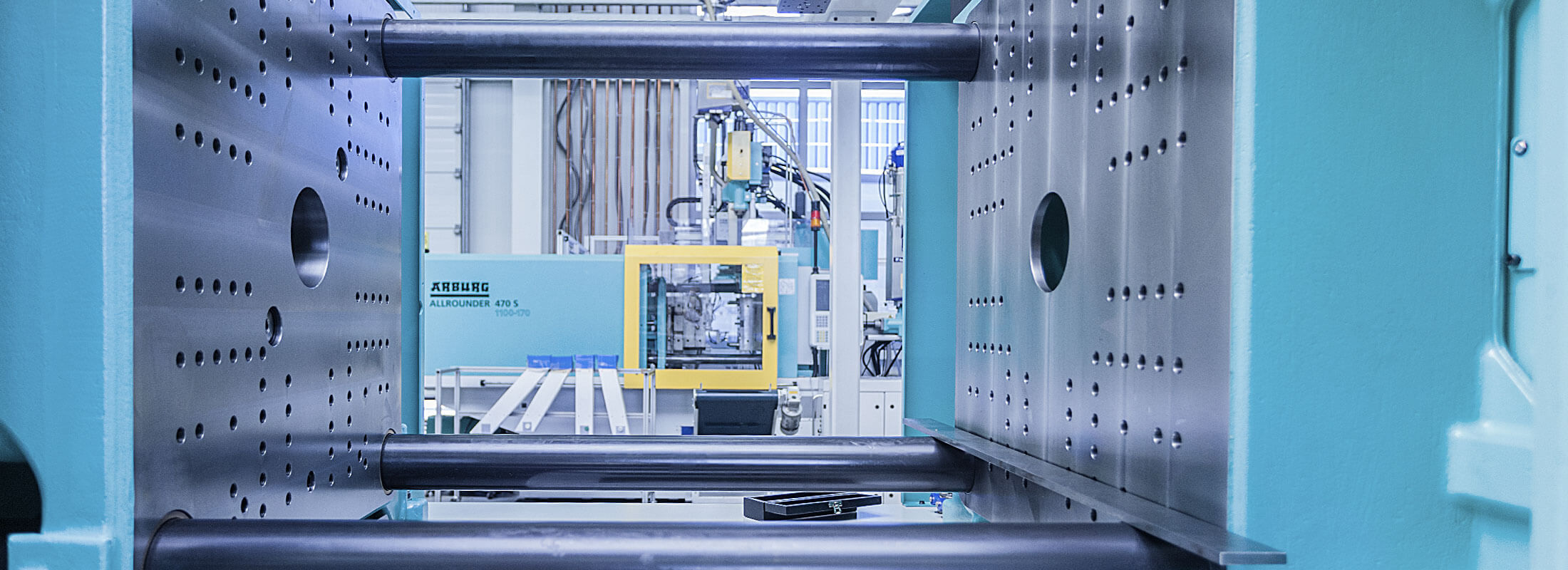

Injection molding with the highest levels of quality and precision

With 65 years of experience, Keune & Lauber GmbH is your competent point of contact for anything relating to plastics manufacturing using various injection molding techniques. Since our company was founded in 1952, we have made every effort to optimize our processes so that we can offer you products with the highest levels of perfection. With a surface area of over 25,000 square meters at our headquarters in Bad Berleburg alone, and with two additional sites, we produce high-quality plastic parts for customers all over the world from the middle of Europe, with the help of modern injection molding technology.

Our core competences

We have established a name for ourselves with the manufacturing of design-oriented operating elements which are used by car manufacturers such as Audi and Porsche, amongst others. In addition, we develop and manufacture high-quality plastic parts for white goods and for the electrical installation sectors which we finish and assemble according to your specifications in extra processing steps. Perfected work processes in plastics manufacturing allow us to quickly implement your requirements and to produce your molded parts to the highest quality possible.

An overview of our competences:

- Technology

- Design

- Tool manufacturing

- Injection molding production

- Painting

- Electroplating

- Controlled area technology

- Laser marking

- Assembly

- Quality management

Innovation, development and production all in the same place

From the initial idea, through to production readiness – as specialists in plastics manufacturing, we pay special attention to providing the best possible quality and a comprehensive service. Our reliable team works with a tremendous amount of dedication to develop and produce comprehensive solutions made from plastic which fully meet your wishes and expectations.

Thanks to our many years of experience, not only are we able to identify current market trends and implement technical innovations, but we are also able to develop these trends and innovations ourselves. Here, we rely on the know-how of our qualified employees who care deeply about continuously improving the performance of our company.

We are able to meet virtually every request from our customers from a technical standpoint. Whether it be injection molding technology for single- or multi-component parts, tool manufacturing, plastics manufacturing with injection molding techniques, surface finishing, mechanical processing or final assembly – with us, you can get everything from the same place.

In-house tool manufacturing

The development and design of the required molds and tools is the first step at the start of our value-added chain. Our process technology engineers work closely with the production process so that we can bring our customers designs to life perfectly. As we design and produce all the tools for the various components ourselves, it is not difficult for us to implement changes quickly and economically at a later date. Keune & Lauber tool manufacturing impresses customers with its flexibility, innovation and short reaction times. The specific expectations of our customers are always the most important thing to us. Expertise, years of experience and a modern manufacturing plant guarantee the quality of our tools and the quality of your plastic parts.

Custom-made injection molded parts according to your wishes

Alongside our in-house tool shop, almost 90 injection molding machines and two painting systems form the foundations of our professional plastics manufacturing. With these systems, we can produce a wide variety of different unit systems with all their relevant components in parallel. Our technical and human resources make it easier for us to be flexible when it comes to lot sizes in batch production. A PPC/PDA system plans and monitors across all production areas through the current production processes and production capacities. We place great importance on the permanent improvement of our process structures, the further development of the automation and the flexible use of the production cells used for plastics manufacturing so that we can continue to meet the high requirements of our customers in the future.

Finishing your plastic parts

Our range of services doesn’t end with the injection molding of your molded parts. So that everything really comes together, we finish the surfaces of the individual elements by painting or printing, for example, and join all the parts together perfectly during the final assembly. Our continuous value-added chain is completed by in-house electro-plating with which we can also perform specific requests for surface finishes, such as the metallization of plastic surfaces for example.

The highest level of quality assurance

Through a meticulous inspection of the optics and haptics with the help of several computer-controlled end-of-line test systems, we ensure that not only do the plastic parts manufactured by us look good, they also function perfectly. Since 2002, our quality management performance has been documented and assured by our compliance with IATF 16949 (formerly ISO/TS 16949).